_shouldn't your part feeding be flexible?

Industry Devices' PartX Flexible feeders provides a new aspect to automated production systems. They enable companies to perform faster changeover of more types of parts—so they can successfully meet the ongoing challenges of high-mix manufacturing.

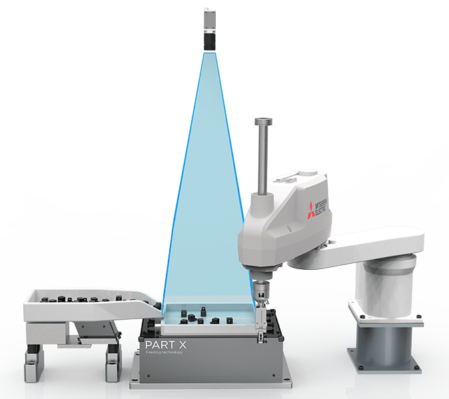

PartX Vibration technology separates and orientates parts for robot picking. A camera locates the correctly orientated parts and sends coordinates to the robot. Additionally, the integrated Vision system detects and adjusts the number of parts inside the flexible feeder.

The PartX product family can be integrated with any vision system and any robot (although we obviously have our favourites!) to build a fully automated parts feeding solution. Improved part positioning is achieved due to our enhanced and upgraded vibration actuators. With its cutting-edge technology, PartX allows parts to be moved in all directions, eliminating the problem of parts accumulating in a corner or on an edge.

Flexible Feeding: How does it work?

- A hopper hold a bulk quantity of product to be fed into the system

- The vibrator plate separates the parts

- A camera system identifies the parts and passes coordinates to the robot

- The robot picks the parts and feeds them into the process

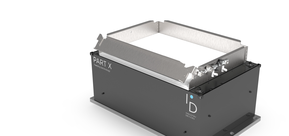

PartX Flexible Feeders

PartX feeders are based on coil actuators on all 4 edges, which have long stroke and force sensors for feedback. With the integration of Carbon Fiber Vibrating plate, achieved stronger vibration due to the decreased weight of components. The electronics and software behind PartX feeders are made with ARM Cortex processors and communication modules from SIEMENS, which provide TCP/IP and PROFINET communication.

Model | Platform Size | Part Size |

PartX Micro | 100x100mm | 1 to 10mm |

PartX S | 150x180mm | 5 to 40mm |

PartX 1 | 200x250mm | 20 to 60mm |

PartX 2 | 275x400mm | 50 to 120mm |

PartX Max | 450x550mm | 100 to 200mm |

| PartX Duo | 2x 200x200mm | 1 to 60mm |

| PartX Cleanroom | 200x200mm | 5 to 40mm |

Custom platform designs

Custom platform designs- FDA Compliant

- ESD-Safe

- Anti-stick

- Anti-roll

AUTOMOTIVE

PARTS

PARTS

CONSUMER

PARTS

PARTS

DELICATE

PARTS

PARTS

ELECTRONIC

PARTS

PARTS

MEDICAL

PARTS

PARTS

After a plug-and-play flexible feeding solution?

Talk to us about VisiFeed...

If you'd like more information about how we can help you